Reflective heat transfer htv vinyl for graphic design

Stock Code: CS-4002-GD- Attachment Type: Iron On

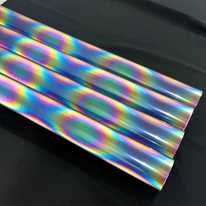

- Daytime Color: Gray

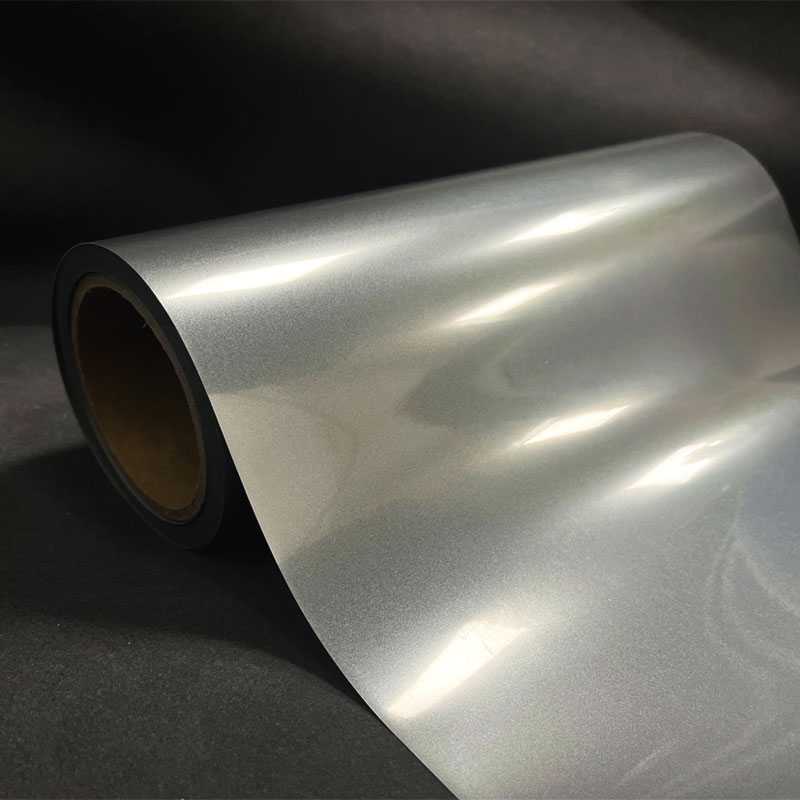

- Composition: PET film and hot melt adhesive

- Reflective coefficient: >260 cd/(lx.m²)

- Home Wash Cycles : >15

- Width: any width from 1cm to 140cm

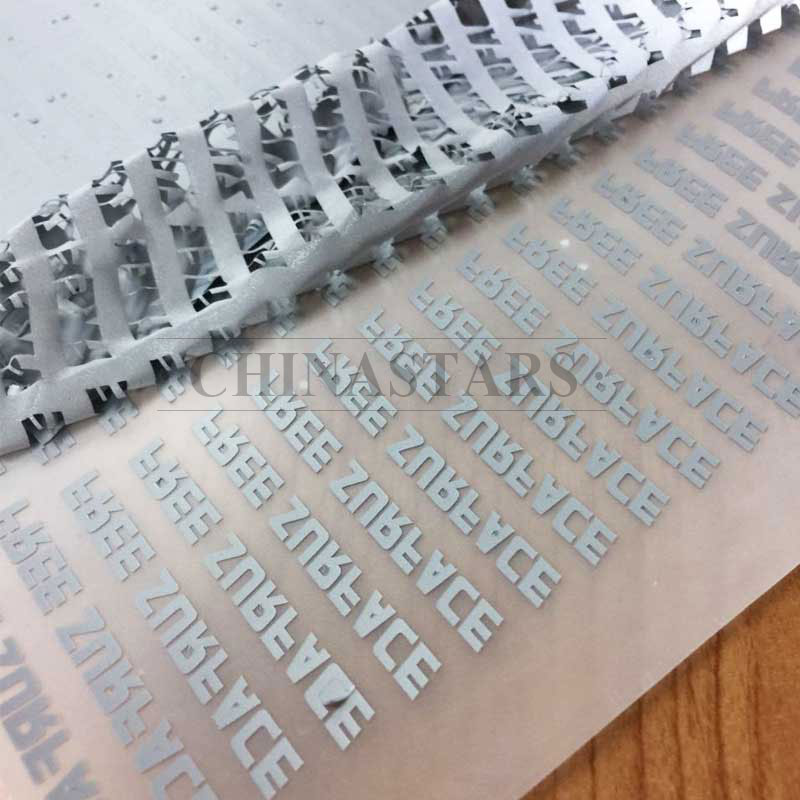

- Application: It is suitable for using a computer or laser to carve a variety of fonts or patterns, and then heat them on all kinds of substrate.

- Packing: 50m/roll, 100m/roll, or customized

DETAILS

- 1. Composed of wide-angle exposed micro-glass beads bonded to a heat-activated adhesive.

- 2. Feature: Thicker PET protective liner for reflective side, easier to cut by plotter or laser machine into graphics, characters, and logos.

- 3. Packing: 50m/roll, 100m/roll, or customized according to customer requirements.

- 4. It can be applied to many non-stretchable fabrics. Ideal for a range of applications, including safety gear, sports apparel, fashion accessories, and more.

- 5. Can be easily applied with a heat press or iron, and can withstand repeated washing and drying without losing its reflective properties.

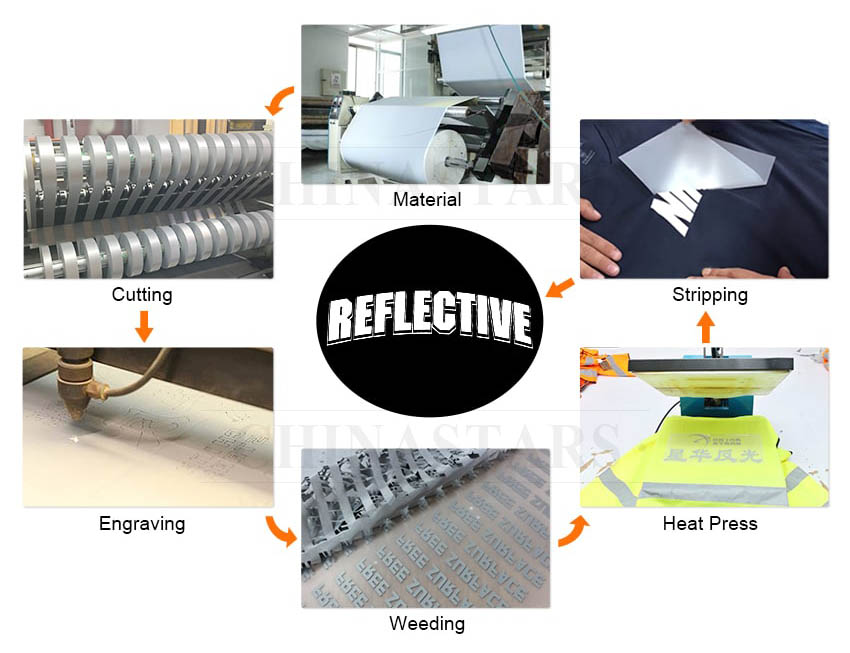

HOW TO USE REFLECTIVE HEAT TRANSFER VINYL

- To apply reflective HTV onto fabric, follow these steps:

- 1. Cut the vinyl into desired strips or logos.

- 2. Weed out the excess vinyl film to leave only the intended design on the carrier film.

- 3. Place the carrier film with the design facing down onto the fabric.

- 4. Apply heat and pressure at the recommended temperature for a specific duration of time.

- 5. Once the heat transfer process is complete, allow the material to cool down.

- 6. Peel off the PET liner from the carrier film to reveal the reflective design on the fabric.

-

Guidelines for CS-4002-GD reflective heat transfer vinyl

-

Heat Press Machine Temperature Dwell Time Line Pressure 140-160℃ 8-20s >0.5kg/cm² Heated Roll Laminator Temperature Rotate Speed Line Pressure 120-140℃ 4-8m/min 4kg/cm² - Before applying the reflective heat transfer vinyl to the actual object, it is advisable to conduct testing and adjustments.

- This will help you understand the effectiveness of the vinyl on a specific object and make necessary adjustments to temperature, pressure, or application time as needed.

-