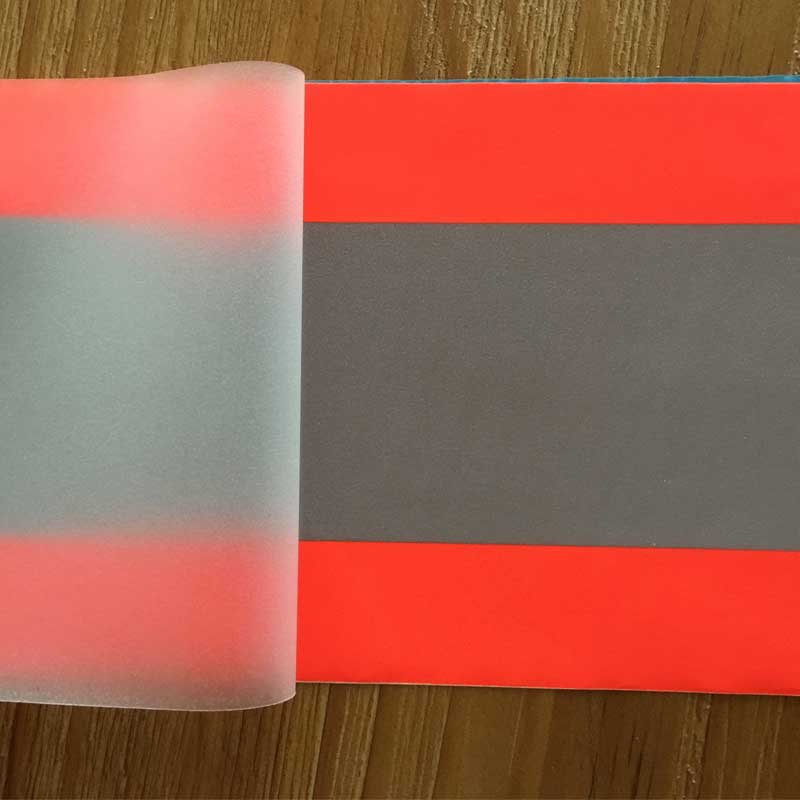

Reflective heat transfer vinyl orange-silver-orange

Stock Code: CSR4013- Attachment Type: Iron On

- Daytime Color: orange-silver-orange

- Backing fabric: PET film + heat melt adhesive

- Reflective coefficient: > 420

- Home Wash Cycles: Up to 25 cycles

- Width: 2'', 3'', 4''

- Certification: EN ISO 20471, ANSI/ISEA 107

- Application: It act as a warning and can be hot pressing on various kinds of base materials.

| Color | orange silver orange |

| Backing Fabric | PET film and heat melt adhesive |

| Reflective Coefficient | R> 420 cd/lx.m2 |

| Washing Instruction | Home wash up to 25 cycles, depending on the condition of the substrates and heat transfer operations |

| Certification | OEKO-TEX 100; EN 20471; ANSI/ISEA 107 |

| Application | used for high visibility clothing, overalls, jacket, when stitching is not recommended. |

| Packing | 50meters/R |

| Departure Port | Ningbo or Shanghai |

1. Composed of wide-angle exposed micro-glass beads bonded to a heat-activated adhesive.

2. Fluorescent properties help to make the material highly visible in daylight, dawn, and dusk.

3. The silver part is certified to major international standards for high visibility material like EN ISO 20471, ANSI/ISEA 107, etc.

1. This heat transfer vinyl is unsuitable for nylon substrates or other water-repellent substrates.

2. This heat transfer film is not suitable for mesh fabric with holes. Heat transfer film on holes without substrates has low adhesive strength and is easily damaged in the wash process or in daily uses.

3. When doing laser engraving or lettering, pay attention to the physical performance of the graphics or letters, especially when the peeled-off heat transfer film is not in good physical performance.

4. Many fabrics can be used as lamination substrates; however, for some substrates that will change color or shape during the process, we highly recommend you choose other low-temperature heat transfer film or use a special operating method to avoid these problems, but pay attention to the adhesion.