The Hidden Complexity Behind Reflective Materials: More Than Just Brightness

"In today’s fast-paced world, reflective materials have become essential across a wide range of industries - from workwear and safety gear to fashion and sports apparel. Their primary function is to enhance visibility in low-light conditions, makes them indispensable for safety and style.

However, while these materials may seem simple at first glance, their creation is anything but. Behind the shine lies a complex process that requires advanced technology, meticulous craftsmanship, and a deep understanding of material science. This article delves into the intricate factors that contribute to the quality and performance of reflective materials, and how Chinastars stands out as a leader in this specialized field."

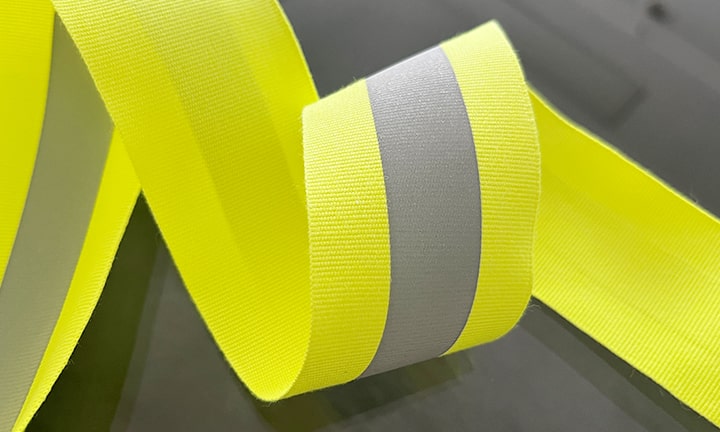

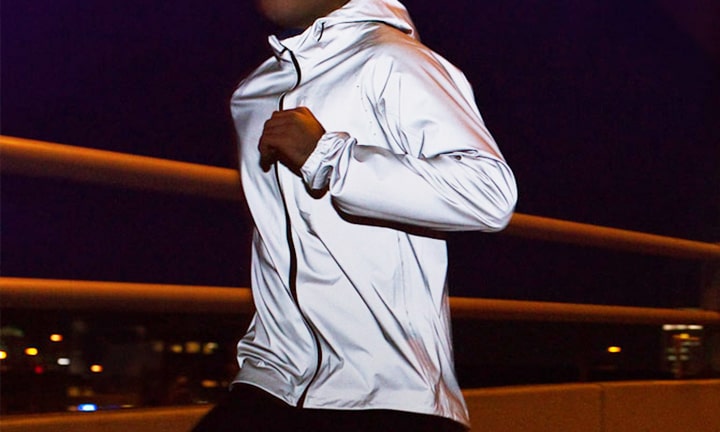

Reflective materials are more than just a visual tool—they are crucial for safety, visibility, and design across various sectors. Whether you're looking at reflective fabric for workwear, heat transfer vinyl for sports apparel, or reflective tape for fashion accessories, the importance of reliable performance cannot be overstated. While their bright, shiny appearance may seem simple, the process of creating high-quality reflective materials involves several key factors that ensure long-term durability, functionality, and safety.

Many customers are drawn to the apparent simplicity of reflective materials. The bright surface and shiny appearance often lead to the assumption that all reflective materials are created equally. The reality, however, is that creating a high-quality reflective material requires precision, technology, and an in-depth understanding of how various factors influence performance and durability.

Why Not All Reflective Materials Are the Same

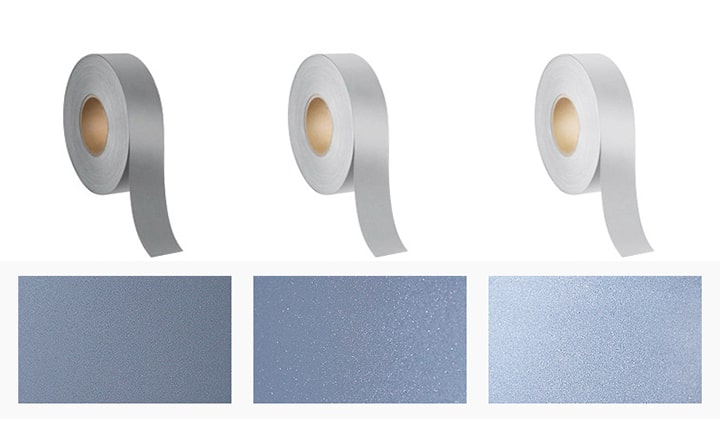

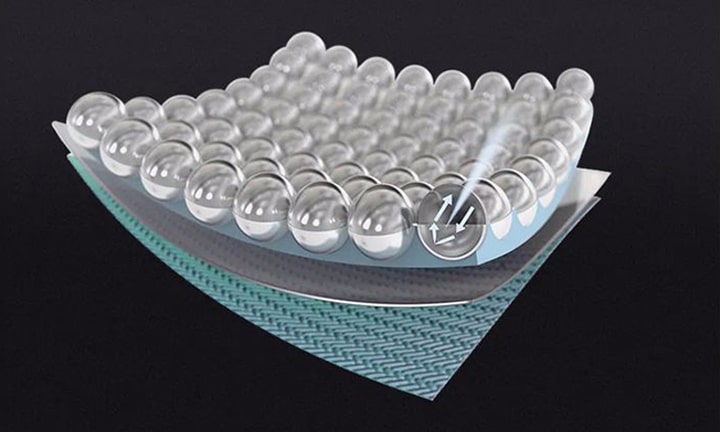

Like any innovative material, the quality of reflective fabrics depends on a delicate balance. What might seem like a simple product is actually the result of a combination of factors: the quality of the reflective beads, the base fabric used, the adhesion process, and the application technology. The perfect balance of these components is what makes a product truly reliable.

- Reflective Beads Quality: High-quality reflective beads are essential to achieving maximum visibility. The size, coating, and alignment of these beads determine how well the material reflects light, especially in low-light or nighttime conditions.

- Fabric Compatibility: The type of fabric used as the base also plays a significant role in the durability and flexibility of the reflective material. Different fabrics react differently to heat, pressure, and adhesive processes during production, affecting the overall performance.

- Durability and Washability: Reflective materials need to withstand not just the initial shine, but also multiple washes and harsh environments.

Challenges in the Reflective Material Market

Despite many brands offering similar shiny surfaces, not all reflective materials are equal in performance or reliability. Some may appear similar at first glance, but cheap alternatives often fall short when it comes to durability, reflectivity, and performance under real-world conditions.

1. Reflectivity Loss After Washes

One of the most common issues with low-quality reflective materials is that they begin to lose their reflectivity after just a few washes, which can lead to reduced visibility. This is especially problematic for high-visibility workwear and safety equipment, where consistent reflectivity is crucial.

2. Poor Adhesion and Application Issues

Another significant challenge is achieving consistent adhesion. Many lower-quality reflective heat transfer vinyls don’t bond properly to fabrics, leading to peeling, cracking, or wrinkling after heat application. This can affect the overall performance of the material and compromise the safety features of the garment.

3. Inconsistent Performance

Reflective materials from different suppliers may perform inconsistently, especially under varying environmental conditions. A material might reflect light well in perfect conditions but fail when exposed to humidity, extreme temperatures, or wear and tear.

The Chinastars Advantage: Why Our Reflective Materials Stand Out

While many brands may offer reflective materials that look the same on the surface, Chinastars Reflective Materials stand out because we understand the complexities behind creating a high-quality, reliable product. With over 20 years of expertise in the reflective materials industry, our focus on innovation, quality control, and certifications ensures that our reflective materials are consistent, durable, and safe for use in any application.

1. Commitment to Quality and Reliability

Chinastars maintains strategic partnerships with suppliers and uses a batch traceability system to track materials by batch number and date. Every raw material undergoes thorough inspection before entering the warehouse, and all products are subjected to triple checks and random checks before shipment. Chinastars' products meet international standards, and the company regularly updates certifications to stay in line with industry requirements.

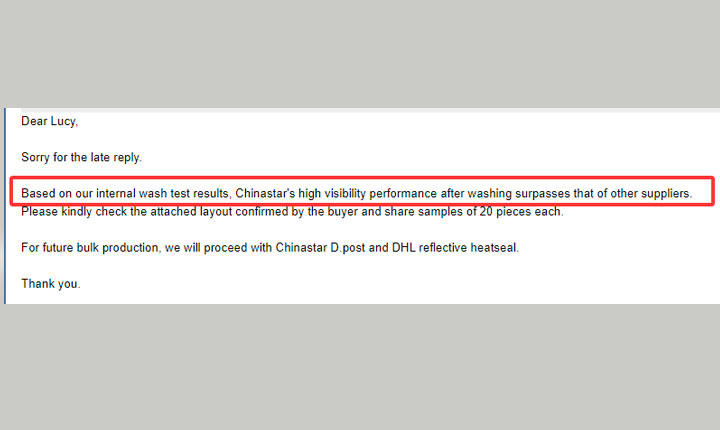

Customer Feedback: A Testament to Quality

Our commitment to quality is reflected in the positive feedback from our customers. For example, one of our clients recently praised the reflective tape for its exceptional performance, stating:

"Based on our internal wash test results, Chinastars’ high visibility performance after washing surpasses that of other suppliers."

2. Certified Quality and Safety Standards

At Chinastars, we don’t just focus on the visual appeal of our products; we also prioritize safety and quality. Our reflective materials are OEKO-TEX certified, meaning they are free of harmful chemicals and safe for use in sensitive environments. We also meet major international certifications such as: EN 20471, ANSI/ISEA 107, AS/NZS 1906, CSA-Z96EN 469, NFPA 2112, NFPA 1971, ISO 9001, etc.

3. Customizable Solutions

At Chinastars, we understand that every business has unique needs. That’s why we offer customizable reflective materials that can be tailored to meet your exact requirements. Whether it’s adjusting the reflectivity, improving washability, adding flame retardant properties, or even creating a specific color or design, we’re committed to delivering the perfect solution for your project.

Our dedicated R&D team, backed by collaboration with experts like the Chinese Academy of Sciences, is constantly working to improve our materials. This allows us to offer high-performance reflective products that match your needs, whether it’s for fashion, workwear, or safety gear. Whatever your idea, we’ll work with you to bring it to life.

4. Support Beyond the Product

At Chinastars, we don’t just sell products—we offer comprehensive support every step of the way. From application guides and video tutorials to on-site training, we make sure that our customers can easily apply our reflective materials, whether they’re located domestically or internationally.

But our support doesn’t stop there. If any issues arise during the use of our materials, we’re committed to resolving them together with our customers. We pride ourselves on our after-sales service and are always ready to provide assistance, with no excuses, to ensure that you get the best results from our products.

The Takeaway: Reflective Materials Are More Than Just Brightness

At first glance, reflective materials might seem like a simple solution—just add a reflective surface, and you’re good to go. But as with any innovative product, the real value comes from understanding the complexity beneath the surface.

In a competitive market, choosing Chinastars means opting for a trusted partner who understands the intricacies of reflective materials and consistently provides solutions that offer lasting value. While the price may not always be the lowest, the focus on superior quality and consistent performance ensures that Chinastars' products stand the test of time.