A introduction of Perforated reflective tape

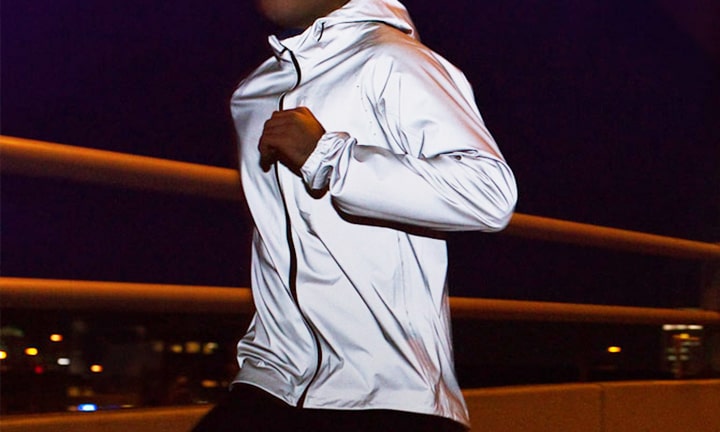

It becomes more and more popular to reprocess the reflective tape into different shapes or patterns. It changes the dull image of reflective tape and makes the garments fresh and fashionable. Perforating is one of the reprocessing ways and it makes the reflective tape breathable and artistic.

Chinastars could perforate various kinds of patterns on different reflective tapes, such as reflective TC tape, reflective FR tape, and reflective heat transfer tape.

In general, there are 2 kinds of perforating methods for reflective tape. One is perforating full wide reflective fabric, usually the full wide is 110cm. This method costs low and it is good for different shapes of application. For example, it is a perfect choice to perforate the reflective fabric and then make the jacket as shell fabric. While this method of production is not good for tape sewing, the sewing is not very strong.

Another way is perforating narrow wide reflective stripe(usually 5cm wide) and making the edge non-perforated. This method costs much higher and the non-perforated edge is good for sewing. It is the perfect choice to apply such stripes on garments and make them special in the market.

Then why does perforating for narrow tape cost much more than wide fabric? Mainly below 2 reasons below that could explain it.

1. Labour costs: for wide tape, we perforate first and then slit it into different sizes, the labor costs could be divided and unit labor costs are much lower. While for narrow tape with a non-perforated edge, we slit the stripes first and then perforate each stripe.

2. Model charge: for wide tape, the model charge is low and it could work for a long time. While for the narrow one, the model charge is high and it is easy to be attritted.